UTG(Ultra Thin Glass)

UTG

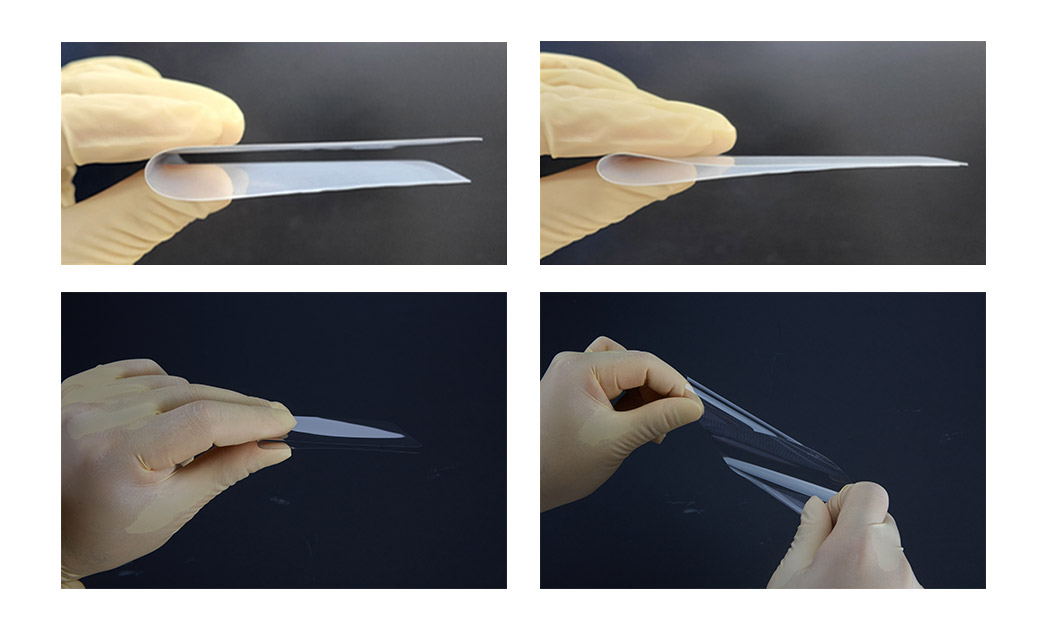

- As a key component of foldable smartphones,

this ultra-thin tempered glass is thinner and more durable than plain tempered glass. - Secured the technology to remove progressive micro-cracks that break the glass upon impact and the chemical strengthening technology to achieve the minimum R value of the glass radius.

- Secured glass surface treatment technology to maintain stable repeatability of 250,000 times.

- Establishment of mass production system by developing dedicated facilities to secure stable productivity and improvement of yield.

- With UTG for foldable phones, we manufacture the glasses in the desired shapes of our customers, with 30~70㎛ thickness, and provide a total solution for PET film lamination.

- Moreover, we are capable of producing large-size UTGs such as tablets, laptops, and monitors, including sizes of 6.7-inches to 8.2-inches for foldable smartphones.

UTG for Foldable Phones

UTG Folding specification

| Thickness | Folding radius | Repeatability |

|---|---|---|

| 30 ㎛ | 0.9R | 200,000cycle |

| 50 ㎛ | 1.5R | 200,000cycle |

| 70 ㎛ | 2.0R | 200,000cycle |

Tablet

Notebook & Large size Monitor

| Specification | ||

|---|---|---|

| Size | 10.1”~ 14” | 15” ~ 17.8” |

| Thickness | 70㎛, 100㎛ | 100㎛ |

| Folding radius | 3.0R | 4.0R |

| Repeatability | 200,000cycle | 200,000cycle |

Size and Thickness of UTG’s Product Line

| Model | 6.7inch | 7.6inch | Note Book(17.8inch) |

|---|---|---|---|

| Thickness | 0.035mm / 0.05mm | 0.3mm / 0.05mm | 0.1mm |

| Size | 156.63 x 71.13 | 165.98 x 125.16 | 359.09 x 272.64 |

| Image |  |  |  |

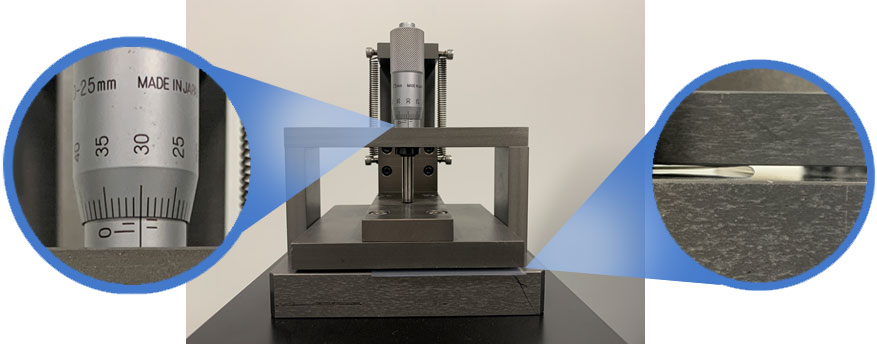

Reliability Folding Test (Repeatability 400,000 Times)

- Environmental Testing Conditions: -20℃ 96hrs after 80℃ 96hr / continuous test (2 seconds at a time)

- Glass Thickness: 50um / 1.5R Folding

UTG Main Process

| Specifications | Equipment Photos | Properties |

|---|---|---|

| Laser Shape Processing |  |

|

| Lamination |  |

|

| Chemical Strengthening |  |

|